How Paper Manufacturers Reduced Their Carbon Footprint

It cannot be denied that paper manufacturing is a process with a high carbon footprint. With the onset of the large-scale mechanized harvesting of wood last century, as well as the increasing demands for huge volumes of paper for the modern printing press, disposable paper became a cheap commodity. This meant that the environmental effects of paper manufacturing soon became a significant worldwide problem.

Growing trees on a large scale and then harvesting them for paper could not remain environmentally sustainable without recycling some of this paper when it was subsequently thrown away. The large-scale consumption and wastage of paper had become completely unacceptable. So, efforts began to produce all kinds of recycled paper, from printing paper to toilet paper.

Why is paper manufacturing not sustainable?

One of the most unsustainable and environmentally damaging aspects of paper manufacturing is the sourcing of the raw material, i.e. the wood or wood pulp needed to make paper. The clearcutting process of growing and harvesting trees, a logging practice where huge swathes of trees are uniformly cut down, has been controversial for decades.

Who can forget images of forests with large patches missing that have been harvested using the clearcutting process? This shocking destruction of the environment not only damages the tree population but also has knock on effects on the bird and animal population who have unwittingly made their homes in a doomed forest.

This type of practice was unpalatable to many and was also shown to be highly environmentally destructive. A new way to source wood pulp for paper was urgently needed and this is where recycling began to come in on a larger scale, meaning less trees needed to be cut down in-order-to produce the paper that the world demanded.

Other environmental concerns around paper manufacturing and disposal included water and air pollution, as well as overflowing landfills. The production of paper pulp from the wood source material puts a strain on environmental resources. In fact, paper mills that are used to make paper contribute heavily to air, water and land pollution.

Reducing the damaging process of paper manufacturing

There was clearly a need to reduce environmentally damaging processes involved in paper manufacture that put this excessive pressure on water supplies and caused air pollution. These issues combined with the detrimental environmental effects of clearcutting have now led to much tighter environmental and governmental regulations on the manufacture of paper.

The pulp and paper industry moved towards reducing sourcing wood from clearcutting practices, instead moving towards using recycled paper. At the same time, solutions were found to reduce water usage, as well as cut greenhouse gas emissions and fossil fuel consumption in the paper manufacturing industry. All this led to a new era of sustainable paper manufacturing.

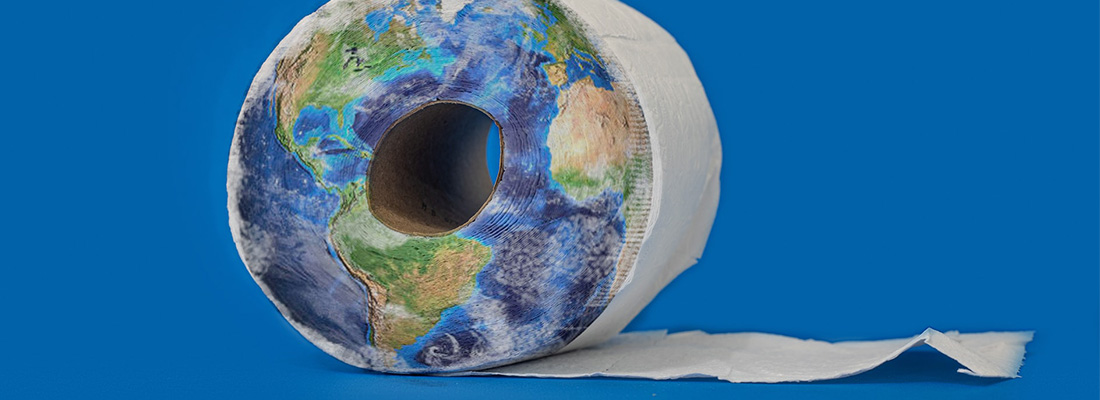

One type of paper that was clogging up the world’s systems, quite literally, was toilet paper. The sheer scale of usage of this essential household item was often too much for sewerage systems to cope with and created a huge demand on the world’s trees for the raw material needed to create millions of tonnes of toilet paper.

Recycled toilet paper

This need for a more sustainable solution is where the concept of recycled toilet paper came in. Although potentially an undesirable concept to people at first, the process used to recycle paper and turn it into toilet tissue made it completely safe, hygienic and sustainable.

To make recycled toilet paper, large bales of recycled paper gathered from different sources are put into a pulping machine at the factory. The paper is mixed with warm water to form a pulp that can then be reformed. An ink removing process is carried out, this is done by injecting the paper pulp with air, making the ink rise to the top in a foam that is then skimmed off.

Water is then squeezed out of the pulp with rollers. Not only does this dry it out but allows it to absorb bleaching chemicals to make the grey pulp both white and hygienically clean. The pulp is then spread on a flat screen that runs through a dryer, transforming it into delicate thin sheets of paper in seconds.

It is a simple process that allows for the millions of tonnes of wastepaper that are produced around the world each year to be recycled into an essential household product, thereby significantly reducing the carbon footprint of this type of paper manufacturing.

Sustainable toilet paper manufacturing

Paper is an easy product to recycle so it was not only environmentally but financially sensible to turn it into a product that previously required wood pulp. Toilet paper is becoming more sustainable in other ways too. Manufacturers are producing coreless products, without the central roll and packaging their toilet rolls in recycled boxes and packaging.

One such manufacturer is BRD Papir KFT, who will be exhibiting next year at the world’s largest cleaning and hygiene show, Interclean in Amsterdam. Other innovative exhibitors like Tork, manufacturer of professional hygiene products, are offering the world’s first recycling service for paper handtowels.

If you want to find out about the latest innovations in sustainable paper manufacturing and recycling, Interclean is the place to go. With a huge range of international exhibitors, including washroom product manufacturers and other types of paper manufacturers, it is the place for innovation. To book your place visit www.intercleanshow.com/amsterdam.

Receive the best newsletter on cleaning & hygiene - straight to your inbox!

We promise never to send you spam and you can unsubscribe at any time!